Bolt modding a Unicomp Model M keyboard.

Well, screw modding, actually, but let's not get technical.

Postscript: A minor adjustment to the screws at the corner of the plate, and now the Ctrl key is behaving and it's working flawlessly.

Want to contact me? Try me at j7l{at}@xec.net.

I've had this keyboard for about five years and it's never really felt good. I got to wondering whether a bolt mod would improve it.

When I opened it up to check out the lay of the land, I found 15 rivets missing.

FIFTEEN. In a five year old keyboard. So a bolt mod it was going to be.

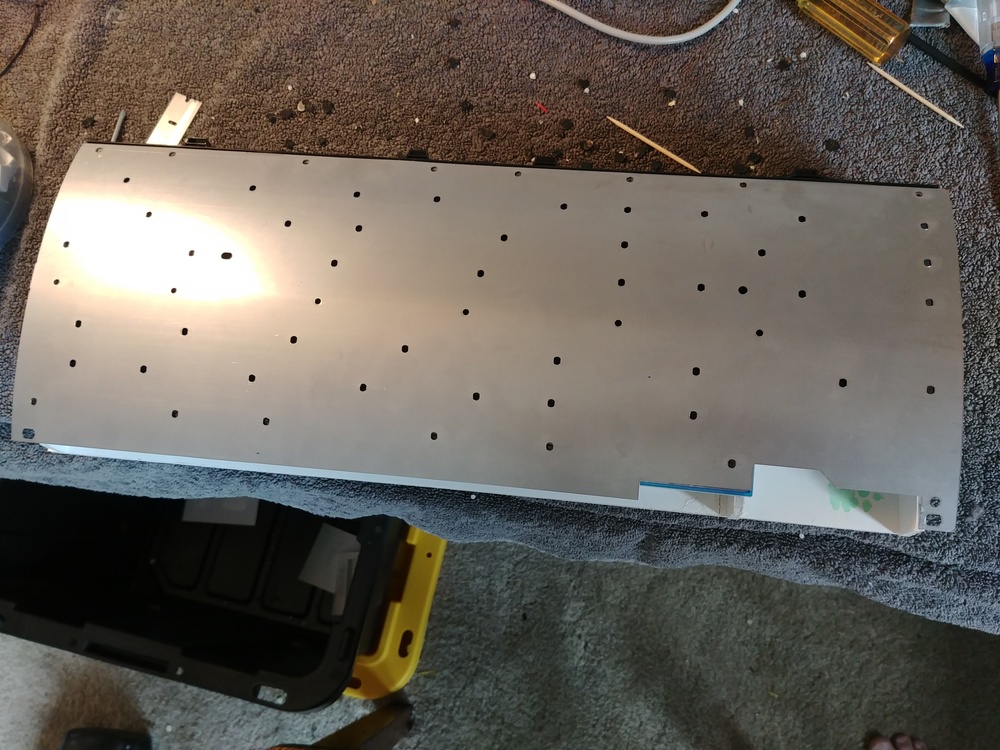

Here's what the top of the barrel plate looks like. The spot at the upper right corner is where the controller (already removed) clips in.

The yellow snot on the spacebar retainer clips is grease. Yes, they greased it. The hair is because I have a beard.

All rivets removed. They weren't that securely ironed down to begin with.

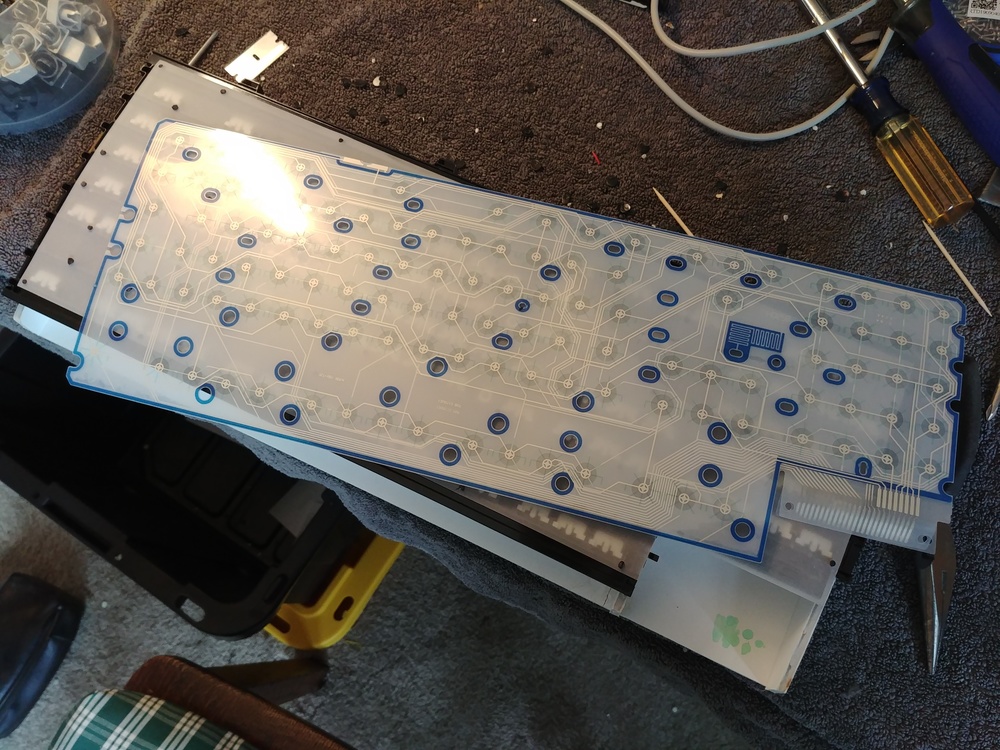

Now this is interesting. The membranes are one sealed assembly. Pretty slick, actually.

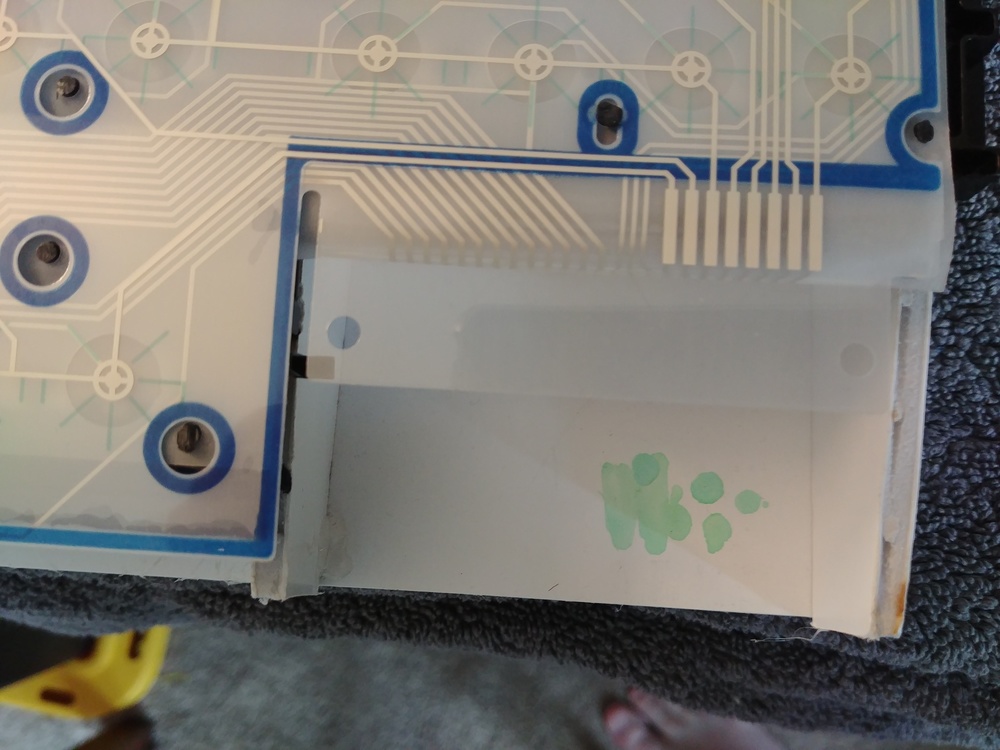

This is where the two membranes that make up the assembly exit to the controller. Only the barrel-side membrane folds over to mate with the controller.

The plate-side membrane contacts extra traces on the barrel-side membrane which extend onto the fold-over.

It's all held in place by a piece of rubber foam and a clip to keep tension where the board presses down on the foam.

Membrane assembly detached.

The customary black rubber sheet found in an IBM unit is replaced by this... stuff. I don't really know what it is. It's stretchy like rubber. Maybe it is.

Closeup of the clip area. A strip of rubber foam goes in that little tray, and the pegs hold both the foam and the folded-over membrane traces.

In these next few pictures I was trying to show molding flaws, but my phone apparently can't focus that close.

This one's almost clear enough. You can see the flaw next to the barrel, a sunken area.

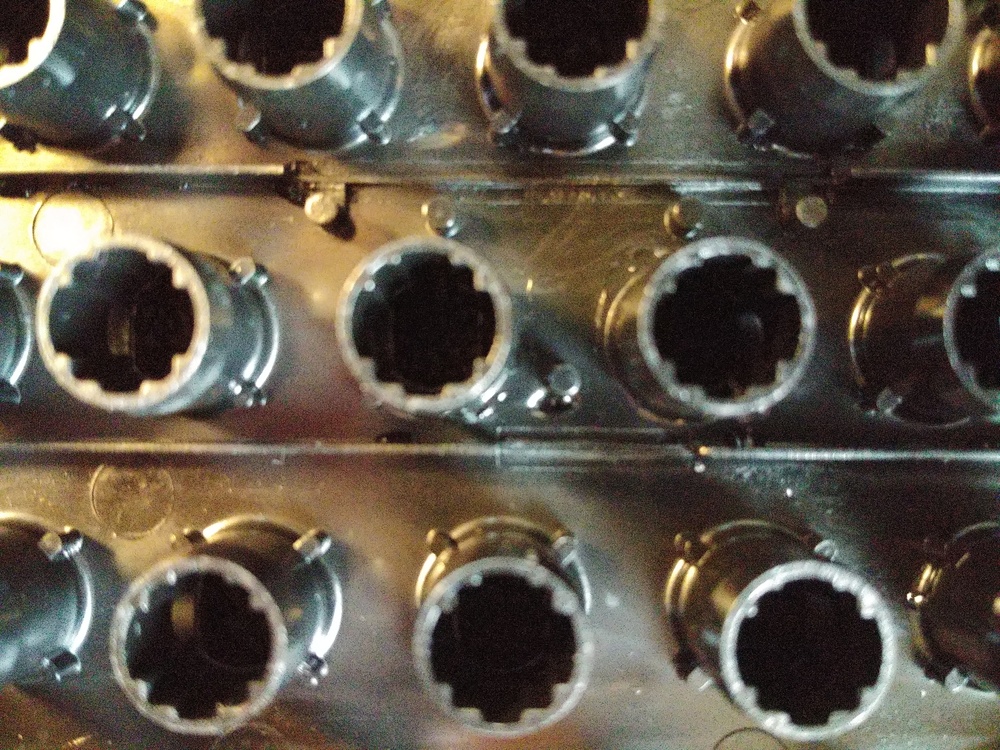

Here you can see really serious flaws right where I need to drill. I didn't know if it was going to work.

But it did work and I put it back together.

Then I experienced the heartbreak and frustration of discovering one of the flippers was out of place. So I had to take it all apart again and fix that.

Cover on.

Keycaps on.

So, the verdict. Did it help?

Ehhhh... kind of. It's a little better than it was, but it's still rough and clunky compared to back-in-the-day ones.

And I still have adjustments to do; I started off writing this page with it, and the Ctrl kept getting stuck on. So I have to do some fine tuning.

I knew Unicomps were more cheaply made, but I wasn't prepared for the barrel plate to be what it was. It looks like a factory second.

On the other hand, the sealed membrane assembly is smart. So there you go. Draw what conclusions you can.

Thank you and good night.

I'm using it with the cover off right now and it sounds a lot better this way. Didn't realize how much the case contributes to the sound.